Lifting Points

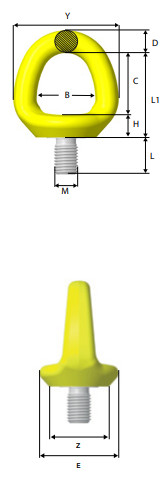

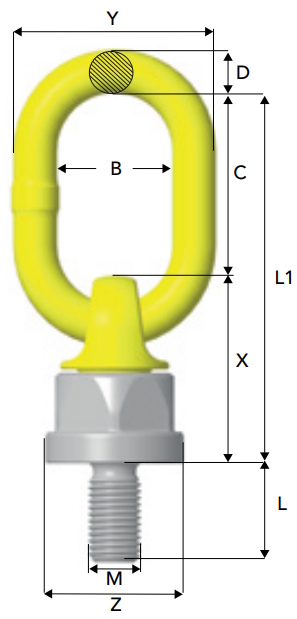

Rotating Eye Lifting Point – RELP

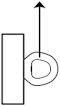

The RELP is a compact and robust lifting point, ideal for top-mounting and when it is important to have quick and easy on-hooking. The lifting point is easy to assemble/disassemble with a standard allen key. On the bolt itself, information such as the working load limit, mounting torque, and manufacturing ID is stamped, so it is always available for the operator.

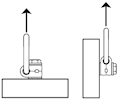

The RELP will automatically adjust to the loading direction which decreases the risk to load it incorrectly and endangering the lifting operation. For sensitive load surfaces the RELP is ideal, as the connecting sling hook will be positioned mainly parallel to the load surface, thus completely avoiding the hook causing damage on impact on the load.

The RELP will automatically adjust to the loading direction which decreases the risk to load it incorrectly and endangering the lifting operation. For sensitive load surfaces the RELP is ideal, as the connecting sling hook will be positioned mainly parallel to the load surface, thus completely avoiding the hook causing damage on impact on the load.

| CODE | M [mm] | L1 [mm] | L [mm] | B [mm] | C [mm] | D [mm] | E [mm] | Y [mm] | Z [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| G10RELPM08G | 8 | 42 | 15 | 28 | 28 | 11 | 40 | 50 | 29 | 0.2 |

| G10RELPM10G | 10 | 42 | 15 | 28 | 28 | 11 | 40 | 50 | 29 | 0.2 |

| G10RELPM12G | 12 | 47 | 20 | 32 | 33 | 13 | 46 | 58 | 38 | 0.3 |

| G10RELPM16G | 16 | 57 | 24 | 39 | 41 | 15 | 53 | 70 | 40 | 0.5 |

| G10RELPM20G | 20 | 60 | 30 | 42 | 43 | 16 | 60 | 78 | 46 | 0.7 |

| G10RELPM24G | 24 | 71 | 36 | 50 | 51 | 19 | 68 | 88 | 44 | 1.1 |

| G10RELPM30G | 30 | 90 | 45 | 60 | 62 | 26 | 85 | 112 | 64 | 2.4 |

| G10RELPM36G | 36 | 104 | 54 | 72 | 72 | 32 | 97 | 136 | 74 | 4.1 |

| G10RELPM42G | 42 | 119 | 63 | 82 | 82 | 38 | 120 | 158 | 91 | 6.7 |

| G10RELPM48G | 48 | 135 | 72 | 94 | 96 | 43 | 142 | 180 | 102 | 9.9 |

| No. of Legs | 1 | 1 | 2 | 2 | 2 Symmetric | 3 & 4 Symmetric | Tightening | ||

|---|---|---|---|---|---|---|---|---|---|

| ANGLE a | 0° | 90° | 0° | 90° | 0°- 90° | 90°- 120° | 0°- 90° | 90°- 120° | Torque |

| SYMMETRIC LOAD (tonnes) |  |  |  |  |  |  | |||

| G10RELPM08G | 0.7 | 0.3 | 1.4 | 0.7 | 0.4 | 0.3 | 0.6 | 0.4 | 10Nm |

| G10RELPM10G | 1.2 | 0.5 | 2.4 | 1.0 | 0.7 | 0.5 | 1.0 | 0.7 | 15Nm |

| G10RELPM12G | 2.0 | 0.8 | 4.0 | 1.6 | 1.1 | 0.8 | 1.6 | 1.2 | 27Nm |

| G10RELPM16G | 3.5 | 1.5 | 7.0 | 3.0 | 2.1 | 1.5 | 3.1 | 2.2 | 60Nm |

| G10RELPM20G | 6.1 | 2.4 | 12.2 | 4.8 | 3.3 | 2.4 | 5.0 | 3.6 | 90Nm |

| G10RELPM24G | 8.1 | 3.3 | 16.2 | 6.6 | 4.6 | 3.3 | 6.9 | 4.9 | 135Nm |

| G10RELPM30G | 12.1 | 4.6 | 24.2 | 9.2 | 6.4 | 4.6 | 9.6 | 6.9 | 270Nm |

| G10RELPM36G | 16.1 | 7.1 | 32.2 | 14.2 | 9.9 | 7.1 | 14.9 | 10.6 | 320Nm |

| G10RELPM42G | 24.0 | 9.1 | 48.0 | 18.2 | 12.7 | 9.1 | 19.1 | 13.6 | 600Nm |

| G10RELPM48G | 32.0 | 12.1 | 64.0 | 24.2 | 16.9 | 12.1 | 25.4 | 18.1 | 800Nm |

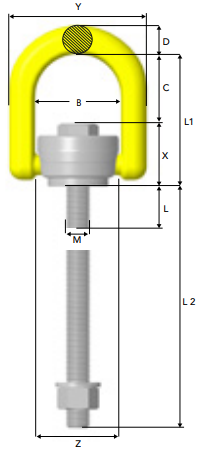

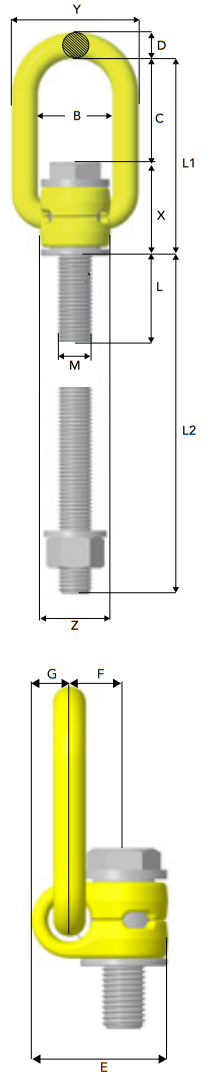

Rotating Lifting Point – RLP

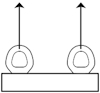

The RLP has an easily dismountable D-ring to enable assembly of wire sling, master link, or hook directly onto the lifting point.

RLP has a hexagon bolt (RFID prepared) to make it easy to disassemble/assemble with a wrench. The bolt is also clearly marked with information such as working load limit, mounting torque, and manufacturer ID. The RLP rotates 360° and pivots 180°, making it strong, flexible, and reliable.

RLP has a hexagon bolt (RFID prepared) to make it easy to disassemble/assemble with a wrench. The bolt is also clearly marked with information such as working load limit, mounting torque, and manufacturer ID. The RLP rotates 360° and pivots 180°, making it strong, flexible, and reliable.

| CODE | M [mm] | L1 [mm] | L [mm] | L2* [mm] | B [mm] | C [mm] | D [mm] | X [mm] | Y [mm] | Z [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| G10RLPM08G | M8 x 1.25 | 62 | 16 | 101 | 42 | 35 | 12 | 27 | 64 | Ø40 | 0.3 |

| G10RLPM10G | M10 x 1.5 | 62 | 16 | 101 | 42 | 35 | 12 | 27 | 64 | Ø40 | 0.3 |

| G10RLPM12G | M12 x 1.75 | 88 | 25 | 120 | 57 | 46 | 19 | 42 | 91 | Ø54 | 1 |

| G10RLPM16G | M16 x 2 | 88 | 25 | 160 | 57 | 46 | 19 | 42 | 91 | Ø54 | 1 |

| G10RLPM20G | M20 x 2.5 | 110 | 36 | 200 | 83 | 55 | 28 | 55 | 133 | Ø80 | 2.9 |

| G10RLPM24G | M24 x 3 | 110 | 36 | 240 | 83 | 55 | 28 | 55 | 133 | Ø80 | 2.9 |

| G10RLPM30G | M30 x 3.5 | 148 | 58 | 300 | 114 | 70 | 34 | 78 | 182 | Ø111 | 7.1 |

| G10RLPM36G | M36 x 4 | 148 | 58 | 300 | 114 | 70 | 34 | 78 | 182 | Ø111 | 7.3 |

| G10RLPM42G | M42 x 4.5 | 190 | 81 | 301 | 149 | 91 | 40 | 99 | 229 | Ø142 | 14.3 |

| G10RLPM48G | M48 x 5 | 190 | 81 | 301 | 149 | 91 | 40 | 99 | 229 | Ø142 | 14.5 |

| * comes with short bolt as standard, long bolts sold separately. | |||||||||||

| No. of Legs | 1 | 1 | 2 | 2 | 2 Symmetric | 3 & 4 Symmetric | Tightening | ||

|---|---|---|---|---|---|---|---|---|---|

| ANGLE a | 0° | 90° | 0° | 90° | 0°- 90° | 90°- 120° | 0°- 90° | 90°- 120° | Torque |

| SYMMETRIC LOAD (tonnes) |  |  |  |  |  | ||||

| G10RLPM08G | 0.8 | 0.4 | 1.6 | 0.8 | 0.5 | 0.4 | 0.8 | 0.6 | 10Nm |

| G10RLPM10G | 1.2 | 0.7 | 2.4 | 1.4 | 0.9 | 0.7 | 1.4 | 1.0 | 15Nm |

| G10RLPM12G | 2.0 | 1.2 | 4.0 | 2.4 | 1.6 | 1.2 | 2.5 | 1.8 | 27Nm |

| G10RLPM16G | 3.2 | 2.0 | 6.4 | 4.0 | 2.8 | 2.0 | 4.2 | 3.0 | 60Nm |

| G10RLPM20G | 5.6 | 2.8 | 11.2 | 5.6 | 3.9 | 2.8 | 5.8 | 4.2 | 90Nm |

| G10RLPM24G | 8.0 | 4.6 | 16.0 | 9.2 | 6.4 | 4.6 | 9.6 | 6.9 | 135Nm |

| G10RLPM30G | 12.0 | 6.0 | 24.0 | 12.0 | 8.4 | 6.0 | 12.6 | 9.0 | 270Nm |

| G10RLPM36G | 14.0 | 8.0 | 28.0 | 16.0 | 11.2 | 8.0 | 16.8 | 12.0 | 320Nm |

| G10RLPM42G | 16.0 | 14.0 | 32.0 | 28.0 | 19.6 | 14.0 | 29.4 | 21.0 | 600Nm |

| G10RLPM48G | 20.0 | 16.0 | 40.0 | 32.0 | 22.4 | 16.0 | 33.6 | 24.0 | 800Nm |

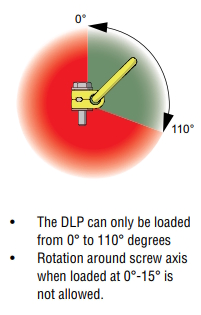

De-centered Lifting Point – DLP

The DLP is designed to be folded over the housing when idle, allowing the lifting point to be almost completely stowed away when not in use.

The closed, oblong link is also equipped with a ‘stay-up’ function for easy on-hooking (for sizes up to M24), especially when there is limited space. This help prevents damage to the load due to impacts from the hook, as well as makes rigging fast and easy. The DLP is ideal in narrow spaces, such as corners or edge position, because the housing has a compact design.

DLP has a hexagon bolt (RFID prepared) to make it easy to disassemble/assemble with a wrench.

The bolt is also clearly marked with information such as working load limit, mounting torque, and manufacturer ID so it is always available to the operator.

The closed, oblong link is also equipped with a ‘stay-up’ function for easy on-hooking (for sizes up to M24), especially when there is limited space. This help prevents damage to the load due to impacts from the hook, as well as makes rigging fast and easy. The DLP is ideal in narrow spaces, such as corners or edge position, because the housing has a compact design.

DLP has a hexagon bolt (RFID prepared) to make it easy to disassemble/assemble with a wrench.

The bolt is also clearly marked with information such as working load limit, mounting torque, and manufacturer ID so it is always available to the operator.

| CODE | M [mm] | L1 [mm] | L [mm] | B [mm] | C [mm] | D [mm] | E [mm] | F [mm] | G [mm] | X [mm] | Y [mm] | Z [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G10DLPM08G | M8 x 1.25 | 78 | 16 | 35 | 48 | 10 | 39 | 14 | 10 | 30 | 55 | 26 | 0.3 |

| G10DLPM10G | M10 x 1.5 | 78 | 16 | 35 | 48 | 10 | 39 | 14 | 10 | 30 | 55 | 26 | 0.3 |

| G10DLPM12G | M12 x 1.75 | 91 | 25 | 35 | 48 | 12 | 51 | 20 | 14 | 44 | 59 | 32 | 0.5 |

| G10DLPM16G | M16 x 2 | 91 | 25 | 35 | 48 | 12 | 51 | 20 | 14 | 44 | 59 | 32 | 0.5 |

| G10DLPM20G | M20 x 2.5 | 145 | 36 | 54 | 88 | 18 | 71 | 28 | 18 | 58 | 90 | 48 | 1.6 |

| G10DLPM24G | M24 x 3 | 145 | 36 | 54 | 88 | 18 | 71 | 28 | 18 | 58 | 90 | 48 | 1.7 |

| G10DLPM30G | M30 x 3.5 | 182 | 58 | 82 | 94 | 26 | 104 | 39 | 27 | 88 | 122 | 75 | 5 |

| G10DLPM36G | M36 x 4 | 182 | 58 | 82 | 94 | 26 | 104 | 39 | 27 | 88 | 122 | 75 | 5.2 |

| G10DLPM42G | M42 x 4.5 | 216 | 81 | 100 | 104 | 36 | 136 | 54 | 34 | 113 | 156 | 110 | 11.6 |

| G10DLPM48G | M48 x 5 | 216 | 81 | 100 | 103 | 36 | 136 | 54 | 34 | 113 | 156 | 110 | 11.9 |

| G10DLPML08G | M8 x 1.25 | 78 | 97.5 | 35 | 48 | 10 | 39 | 14 | 10 | 30 | 55 | 26 | |

| G10DLPML10G | M10 x 1.5 | 78 | 97.5 | 35 | 48 | 10 | 39 | 14 | 10 | 30 | 55 | 26 | |

| G10DLPML12G | M12 x 1.75 | 91 | 118 | 35 | 48 | 12 | 51 | 20 | 14 | 44 | 59 | 32 | |

| G10DLPML16G | M16 x 2 | 91 | 158 | 35 | 48 | 12 | 51 | 20 | 14 | 44 | 59 | 32 | |

| G10DLPML20G | M20 x 2.5 | 145 | 198 | 54 | 88 | 18 | 71 | 28 | 18 | 58 | 90 | 48 | |

| G10DLPML24G | M24 x 3 | 145 | 238 | 54 | 88 | 18 | 71 | 28 | 18 | 58 | 90 | 48 | |

| G10DLPML36G | M30 x 3.5 | 182 | 295 | 82 | 94 | 26 | 104 | 39 | 27 | 88 | 122 | 75 |

| No. of Legs | 1 | 2 | 2 Symmetric | 3 & 4 Symmetric | Tightening | ||

|---|---|---|---|---|---|---|---|

| ANGLE α | 0° < α < 90° | 0° < α < 90° | 0 - 90° | 90°- 120° | 0 - 90° | 90°- 120° | Torque |

| SYMMETRIC LOAD (tonnes) |  |  |  |  | |||

| G10DLPM08G | 0.35 | 0.70 | 0.5 | 0.35 | 0.7 | 0.5 | 10Nm |

| G10DLPM10G | 0.65 | 1.3 | 0.9 | 0.65 | 1.4 | 1.0 | 15Nm |

| G10DLPM12G | 1.0 | 2.0 | 1.4 | 1.0 | 2.1 | 1.5 | 27Nm |

| G10DLPM16G | 1.8 | 3.6 | 2.5 | 1.8 | 3.7 | 2.7 | 60Nm |

| G10DLPM20G | 2.6 | 5.2 | 3.6 | 2.6 | 5.4 | 3.9 | 90Nm |

| G10DLPM24G | 4.1 | 8.2 | 5.7 | 4.1 | 8.6 | 6.1 | 135Nm |

| G10DLPM30G | 5.0 | 10.0 | 7.0 | 5.0 | 10.5 | 7.5 | 270Nm |

| G10DLPM36G | 7.0 | 14.0 | 9.8 | 7.0 | 14.7 | 10.5 | 320Nm |

| G10DLPM42G | 15.0 | 30.0 | 21.0 | 15.0 | 31.5 | 22.5 | 600Nm |

| G10DLPM48G | 20.0 | 40.0 | 28.0 | 20.0 | 42.0 | 30.0 | 800Nm |

Ball-bearing Lifting Point – BLP

The BLP is a versatile lifting point and can be safely used for most applications. The ball-bearings in the BLP allow the load to be rotated during the lift, which is especially good when maintenance is needed on heavy tools and other types of equipment.

If the load surface is sensitive to impacts or scratches, the BLP is a good choice because it builds out from the load, which makes it less likely that the lifting equipment will come in contact and cause damage. The housing (RFID prepared) of the BLP is in-house drop-forged for increased strength and has a hexagon shape for easy mounting and dismounting. The housing is also clearly marked with information such as working load limit, mounting torque, and manufacturer ID so it is always available to the operator

| CODE | M [mm] | L1 [mm] | L [mm] | B [mm] | C [mm] | D [mm] | X [mm] | Y [mm] | Z [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| G10BLPM08G | M8 x 1.25 | 112 | 16 | 35 | 55 | 13 | 57 | 62 | 42 | 0.6 |

| G10BLPM10G | M10 x 1.5 | 112 | 20 | 35 | 55 | 13 | 57 | 61 | 42 | 0.6 |

| G10BLPM12G | M12 x 1.75 | 112 | 24 | 35 | 55 | 13 | 57 | 61 | 42 | 0.6 |

| G10BLPM16G | M16 x 2 | 112 | 30 | 35 | 55 | 13 | 57 | 61 | 42 | 0.6 |

| G10BLPM20G | M20 x 2.5 | 126 | 30 | 34 | 51 | 17 | 75 | 67 | 59 | 1.3 |

| G10BLPM24G | M24 x 3 | 145 | 36 | 50 | 70 | 17 | 75 | 84 | 59 | 1.5 |

| G10BLPM30G | M30 x 3.5 | 102 | 45 | 54 | 96 | 22 | 106 | 99 | 74 | 3.4 |

| G10BLPM36G | M36 x 4 | 102 | 54 | 54 | 96 | 22 | 106 | 99 | 74 | 3.5 |

| G10BLPM42G | M42 x 4.5 | 242 | 63 | 70 | 120 | 28 | 122 | 127 | 93 | 6.5 |

| G10BLPM48G | M48 x 5 | 242 | 72 | 70 | 120 | 28 | 122 | 127 | 93 | 6.8 |

| No. of Legs | 1 | 1 | 2 | 2 | 2 | 2 Symmetric | 3 & 4 Symmetric | Tightening | ||

|---|---|---|---|---|---|---|---|---|---|---|

| ANGLE a | 0° | 90° | 0° | 0°- 45° | 90° | 0°- 90° | 90°- 120° | 0°- 90° | 90°- 120° | Torque |

| SYMMETRIC LOAD (tonnes) |  |  |  |  |  |  | ||||

| G10BLPM08G | 0.6 | 0.3 | 1.2 | 0.4 | 0.6 | 0.4 | 0.3 | 0.6 | 0.45 | 10Nm |

| G10BLPM10G | 1.0 | 0.5 | 2.0 | 0.7 | 1.0 | 0.7 | 0.5 | 1.3 | 0.75 | 15Nm |

| G10BLPM12G | 1.5 | 0.75 | 3.0 | 1.1 | 1.5 | 1.1 | 0.75 | 1.5 | 1.1 | 27Nm |

| G10BLPM16G | 3.0 | 1.5 | 6.0 | 2.1 | 3.0 | 2.1 | 1.5 | 3.1 | 2.2 | 60Nm |

| G10BLPM20G | 5.0 | 2.5 | 10.0 | 3.5 | 5.0 | 3.5 | 2.5 | 5.2 | 3.7 | 90Nm |

| G10BLPM24G | 7.0 | 4.0 | 14.0 | 5.6 | 8.0 | 5.6 | 4.0 | 8.4 | 6.0 | 135Nm |

| G10BLPM30G | 12.0 | 6.0 | 24.0 | 8.4 | 12.0 | 8.4 | 6.0 | 12.6 | 9.0 | 270Nm |

| G10BLPM36G | 14.0 | 8.0 | 28.0 | 11.2 | 16.0 | 11.2 | 8.0 | 16.8 | 12.0 | 320Nm |

| G10BLPM42G | 16.0 | 10.0 | 32.0 | 14.0 | 20.0 | 14.0 | 10.0 | 21.0 | 15.0 | 600Nm |

| G10BLPM48G | 18.0 | 13.0 | 36.0 | 18.2 | 26.0 | 18.2 | 13.0 | 27.3 | 19.5 | 800Nm |

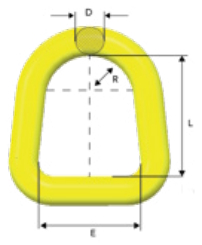

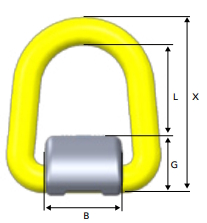

MASTER LINK D – D

| CODE | WLL [t} | E [mm] | D [mm] | L [mm] | R [mm] | WEIGHT [kg] | |

|---|---|---|---|---|---|---|---|

| D-14-10 | 2.5 | 55 | 14 | 65 | 24 | 0.4 | |

| D-17-10 | 4.0 | 64 | 17 | 62 | 29 | 0.5 | |

| D-22-10 | 7.0 | 76 | 22 | 90 | 33 | 1.0 | |

| D-27-10 | 10.0 | 85 | 27 | 98 | 38 | 1.9 | |

| D-32-10 | 16.0 | 114 | 32 | 139 | 50 | 3.5 | |

4:1 Design Factor

The load bearing width must be at least 0.5 x E

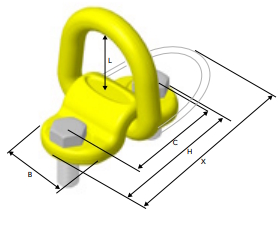

WELDABLE LIFTING POINT – WLP

| CODE | WLL [t] | B [mm] | G [mm] | L [mm] | X [mm] | WEIGHT [kg] | |

|---|---|---|---|---|---|---|---|

| G10WOLP025G | WLP-2.5T | 2.5 | 50 | 27 | 53 | 95 | 0.5 |

| G10WOLP04G | WLP-4T | 4.0 | 58 | 34 | 48 | 97 | 0.5 |

| G10WOLP07G | WLP-7T | 7.0 | 64 | 41 | 73 | 135 | 1.8 |

| G10WOLP10G | WLP-10T | 10.0 | 65 | 52 | 73 | 152 | 3.4 |

| G10WOLP16G | WLP-16T | 16.0 | 90 | 66 | 105 | 203 | 6.7 |

4:1 Design Factor

Supplied with bolt and spring for stay up function.

Master Link measurements , see Master Link D above.

Screw-on LIFTING POINT – sLP

| CODE | WLL [t] | B [mm] | C [mm] | H [mm] | L [mm] | M [mm] | [mm] | BOLT PROTRUSION | WEIGHT [kg] | |

|---|---|---|---|---|---|---|---|---|---|---|

| SLP-1T | 1.0 | 50 | 72 | 98 | 54 | M14 | 139 | 25 | 0.8 | |

| SLP-3.0 | 3.0 | 58 | 84 | 114 | 49 | M16 | 144 | 28 | 1.3 | |

| SLP-5T | 5.0 | 64 | 116 | 160 | 71 | M20 | 203 | 34 | 2.6 | |

4:1 Design Factor

Supplied with bolt and spring for stay up function.

Master link measurements, see Master Link D above.

Supplied with bolt and spring for stay up function.

Master link measurements, see Master Link D above.

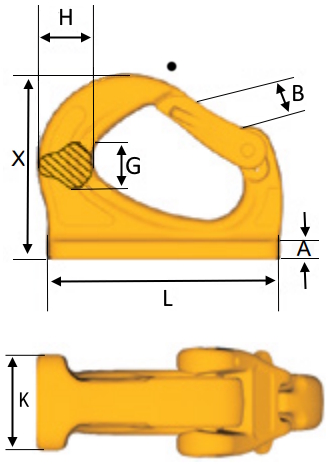

UNIVERSAL WELD-On Hook – UKN

| CODE | B [mm] | G [mm] | H [mm] | K [mm] | WLL [t] | L [mm] | A [mm] | X [mm] | WEIGHT [kg] | |

|---|---|---|---|---|---|---|---|---|---|---|

| G8WOBH0075G | UKN-0.75* | 20 | 13 | 20 | 19 | .75 | 81.5 | 5 | 56 | 0.2 |

| G8WOBH01G | UKN-1* | 27 | 17 | 25 | 25 | 1.0 | 95 | 6 | 72 | 0.6 |

| G8WOBH02G | UKN-2* | 33 | 20 | 30 | 30 | 2.0 | 114 | 8 | 86 | 0.9 |

| G8WOBH03G | UKN-3 | 30 | 23 | 32 | 35 | 3.0 | 132 | 10 | 105 | 1.3 |

| G8WOBH04G | UKN-4 | 30 | 29 | 38 | 42 | 4.0 | 140 | 11 | 114 | 2.0 |

| G8WOBH05G | UKN-5 | 34 | 30 | 47 | 45 | 5.0 | 165 | 12 | 131 | 3.2 |

| G8WOBH08G | UKN-8 | 34 | 40 | 51 | 50 | 8.0 | 172 | 13 | 133 | 3.6 |

| G8WOBH10G | UKN-10 | 47 | 43 | 58 | 55 | 10.0 | 220 | 14 | 170 | 8.2 |

| G8WOBH15G | UKN-15 | 55 | 50 | 67 | 60 | 15.0 | 240 | 15 | 188 | 9.8 |

| G8WOBH20G | UKN-20 | 65 | 60 | 85 | 60 | 20.0 | 275 | 15 | 207 | 12.4 |

Welding plate slightly curved ** Safety factor 5:1 Fulfills requirements in: EN 474-1

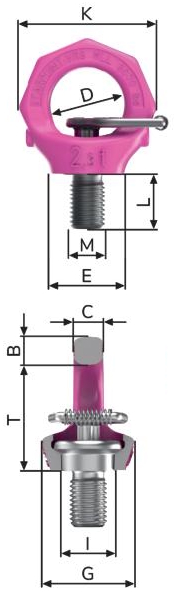

starpoint – VRS-f

Non-detachable ICE-Bolt made of patent steel (M6–M24), thus reducing the risk of using unsuitable standard bolts. Special bolt for safe deep temperature usage with higher toughness and thus higher bending strength as well as less wear.

The WLL information corresponds with the min. WLL (worst case scenario) in all loading directions. Higher WLL by optimised attachment or application.

| CODE | WLL [t] | M [mm] | T [mm] | L [mm] | B [mm] | C [mm] | D [mm] | E [mm] | G [mm] | K [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| G10EBM06RUD | 0.1 | 6 | 28 | 9 | 9 | 7 | 20 | 23 | 28 | 37 | 0.07 |

| G10EBM10RUD | 0.4 | 10 | 35 | 15 | 11 | 9 | 25 | 25 | 30 | 47 | 0.12 |

| G10EBM12RUD | 0.75 | 12 | 42 | 18 | 13 | 10 | 30 | 30 | 34 | 56 | 0.21 |

| G10EBM16RUD | 1.5 | 16 | 49 | 24 | 15 | 13 | 35 | 36 | 40 | 65 | 0.36 |

starpoint – VRM

The WLL information corresponds with the min. WLL (worst case scenario) in all loading directions. Higher WLL by optimised attachment or application.

| CODE | WLL [t] | M [mm] | T [mm] | L [mm] | B [mm] | C [mm] | D [mm] | E [mm] | G [mm] | K [mm] | WEIGHT [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| G10ENM12RUD | 0.75 | 12 | 42 | 17 | 13 | 10 | 30 | 30 | 34 | 56 | 0.18 |

| G10ENM16RUD | 1.5 | 16 | 49 | 21 | 15 | 13 | 35 | 36 | 40 | 65 | .32 |

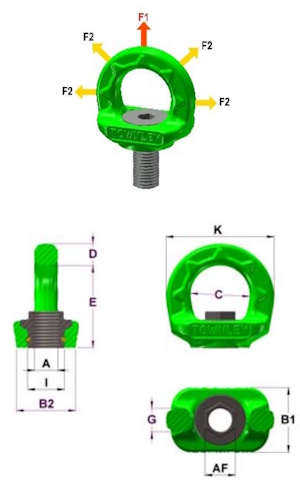

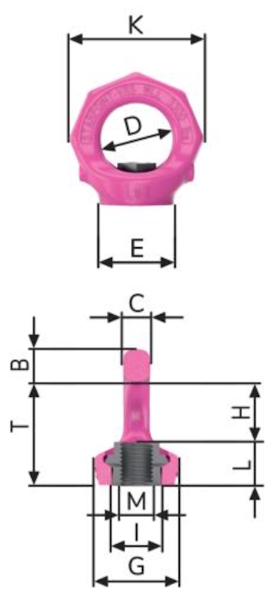

Townley Swivel Eye Nut

Forged from high tensile alloy steel

Tempered

100% electromagnetic crack testing to AS1171

Hi-visibility powder coating to AS4506

Manufactured exclusively from Australian Made Steel

Tempered

100% electromagnetic crack testing to AS1171

Hi-visibility powder coating to AS4506

Manufactured exclusively from Australian Made Steel

| CODE | Metric | WLL F1 [t] | WLL F2 [t] | A [mm) | B2 [mm] | C [mm] | D [mm] | E [mm] | G [mm] | I [mm] | K [mm] | L [mm] | N [mm] | Torque [Nm] | AF [mm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G10ENM20TDF | M20 | 6.0 | 2.3 | 48 | 42 | 39 | 16 | 56 | 16 | 28 | 69 | 30 | 12 | 105 | 24 | 0.6 |

| G10ENM24TDF | M24 | 8.0 | 3.2 | 56 | 50 | 50 | 19 | 71 | 19 | 33 | 86 | 36 | 14 | 182 | 27 | 1.1 |